Stargroup: leadership in consulting and innovation for tube processing. The case of Caldaie Ravasio

Stargroup puts the customer and his specific needs at the centre of the development of tube processing machinery and plants.

A clear example of this approach is highlighted in the article published in the April edition of PubliTec's 'Deformation' magazine, where the case of Caldaie Ravasio is analysed.

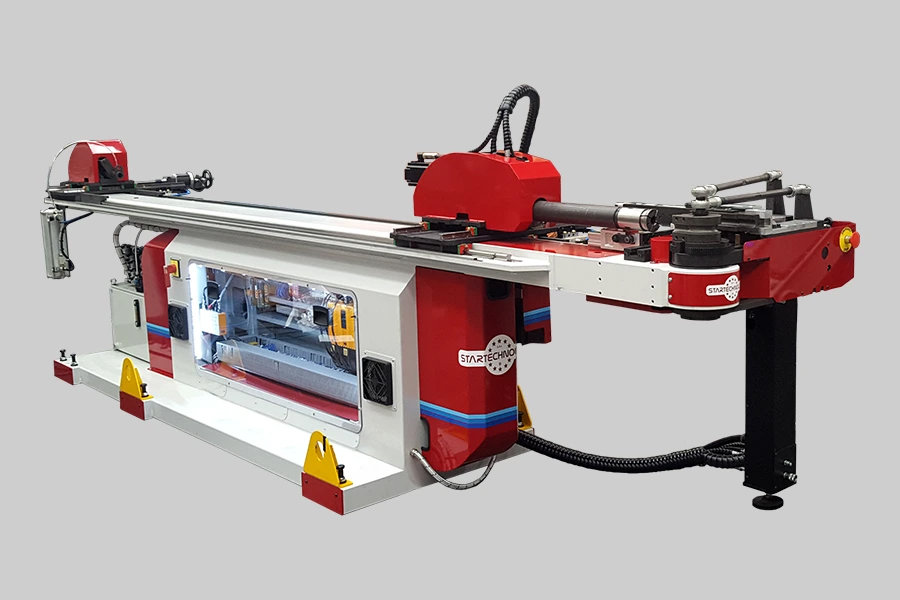

The latter, through Stargroup, purchased an EvoBend 45 hybrid tube bender, customised for the manufacture of the internal copper tube circuitry in its heat pumps.

Pre-sales consulting: customisation and technology at the service of the customer

Every consultancy process offered by Stargroup begins with a detailed examination of the customer's needs, covering aspects such as bending, punching, forming and other tube-specific processes. This pre-sales service not only ensures that each machine is perfectly matched to the customer's production requirements, but is also a clear indicator of the professionalism, experience and expertise that sets Stargroup apart in its field.

Thanks to this consultancy, Caldaie Ravasio was able to understand which technological solution best suited its production needs. The decision to invest in a pipe bender was motivated by the need to realise a circuit with copper pipes varying in diameter from 16 to 64 millimetres, containing an average of 25 bends per product.

'The first impression was immediately positive because we found people capable of understanding the needs of a reality like ours,' commented Ravasio.

Delivering a tailor-made product

The goal was to double production, while keeping time and personnel unchanged, and to improve the quality of the end product.

After careful evaluation, including analysis, comparisons and site visits, Stargroup proposed the EvoBend 45 hybrid tube bending machine as the optimal solution, in an ad hoc developed version called HD. The customisation of the machine allows Caldaie Ravasio to bend also tubes with a larger diameter than the one normally processable with an EvoBend 45, fully meeting the customer's requirements.

'Our goal is to make the customer's process more efficient and cost-effective thanks to our know-how, which covers all tube processing, from cutting to shaping, punching and bending,' stresses Erika Carbone, Sales & Marketing Coordinator at Stargroup.

The introduction of this machinery changed Caldaie Ravasio's production cycle, drastically decreasing the use of commercial bends welded to straight pipes and replacing them with a single pipe bent with the previous geometry and without any welding. This allowed the customer to double production using the same number of operators, effectively responding to growing market demand.

Stargroup's ongoing support, which assisted the company before and after installation and answered any emerging questions, also played a crucial role in this success.

Dynamism in the tube processing sector

In addition to this positive experience, Stargroup has seen strong interest in its technologies, especially bending technology, from companies producing heat pumps, heat exchangers and similar systems.

'In these sectors,' explains Stefano Dal Lago, General Manager of Stargroup, 'tube bending technology can replace the classic processing of cut-to-length tube with a welded bend. Regardless of the material (copper, stainless steel or iron) this type of replacement brings inevitable aesthetic, economic and functional advantages. These are companies that choose to bring about a real change in production mentality and have often never bent. I therefore believe that our ability to guide the customer towards the choice of the right technology and support him in redesigning the production process can be an important added value.'

Read the article