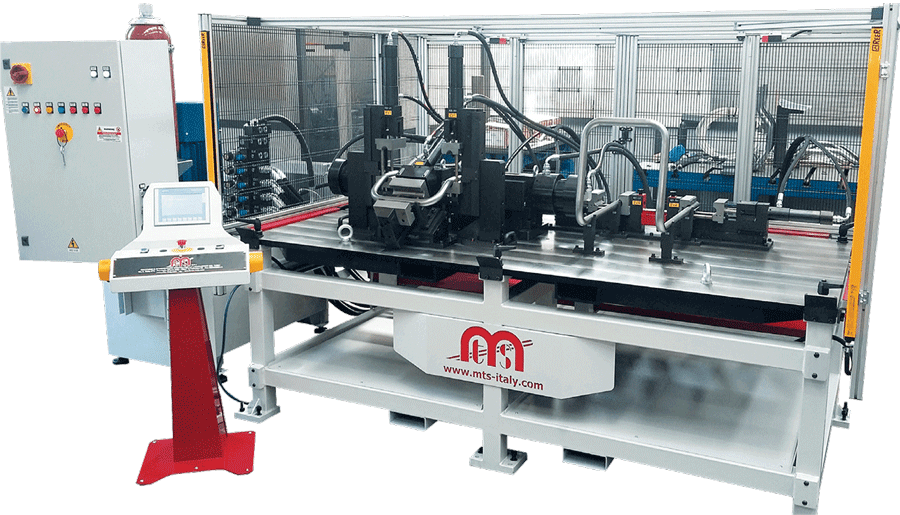

All-In Work benches

Work benches

Work benches

Tube punching, tapering, blading, end forming and pipe notching machines

Main application fields

The All-In work bench can be equipped with automatic, semi-automatic or manual loading / unloading. Operator safety is top priority and all safety systems and devices are fully compliant with the CE/UL directives.

Main features

- Work benches made with fixed or removable plates.

- Dimensions of benches and plates customizable according to the diameters and lengths of the tubes to be processed.

- Wide range of profiles and different metal materials can be processed.

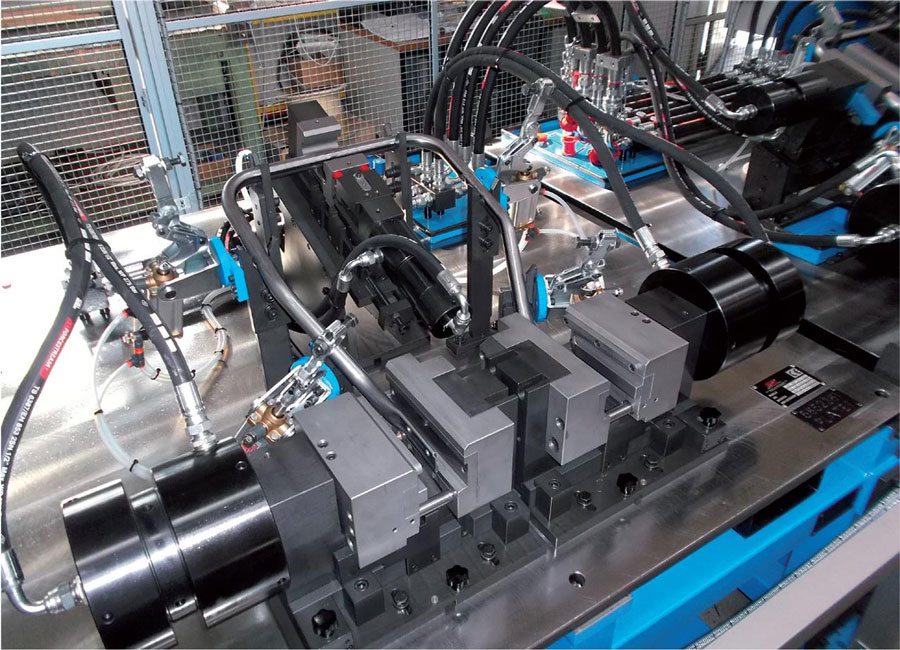

- Punching unit with mandrel to avoid deformation of the profile.

- Self-centering supports to facilitate manual or fully automatic loading and unloading operations.

- Units for punching, notching, cutting, flattering, tapering and swaging.

- Hydraulic unit consisting of tank, motor, pumps, solenoid valves and heat exchanger.

Advantages

- High productivity thanks to the machining of parts in a single work cycle.

- Units can be repositioned on the plates to adapt them to new processes.

- User-friendly thanks to simple and effective graphic interfaces for the operator.

- Reduced maintenance thanks to the use of qualified commercial components and accurate mechanical processing performed internally.

- Quick replacement of the removable plates thanks to the quick hydraulic couplings and pre-wired plugs for the electrical connection.